Which Dyneema® braid for which use ?

Are you looking for a Dyneema® braid, but you don’t know which one to choose? Follow the purchase guide and find the product suitable for the rope’s use: lashings, loops, textile shackles, strops, cascade mounted block and tackles, standing rigging… Technique lovers, or those who wish to try, will find all the explanations regarding the properties of the different Dyneema® braids, depending on the fibre treatment or the braiding pitch.

DYNEEMA®: Which braid should you choose ?

Dyneema® ropes are hollow braids whose plaits are made of several fibres (high modulus polyethylene). The rope’s characteristics depend on how the plaits are assembled and on the treatment applied before and after braiding. The braiding and treatment of the braid affect the quality and properties of the rope. These parameters are important elements to take into consideration when choosing a Dyneema® braid. It is important to use a rope suited to its application. Stiffness, chafing resistance, easy splicing: What is the priority ?

Torsion of Dyneema® twines.

Before braiding, the plaits are twisted around themselves, following a specific twisting direction. It is possible to differentiate the S torsion direction (the twine is twisted to the right) and the Z torsion direction (the twine is twisted to the left). Re-twisting of plaits serves two purposes. The first is to balance the fibres of Dyneema®: They adjust to each other’s length. The second is for protection against chafing: Once twisted, the twines are more resistant to chafing, as torsion gives them a rounded shape.

Braiding pitch

The braiding of fibre corresponds to the assembly phase of plaits. The tighter the braiding pitch is, the wider the angle of the plaits is, in relation to the axis of the rope. And, on the other hand, the longer the braiding pitch is, the more aligned the plaits are along the axis of the rope. The type of braiding directly affects the stiffness of the final product. A Dyneema® rope with a short braiding pitch is more elastic and more resistant to chafing. A rope with a long braiding pitch is stiffer and more sensitive to chafing. It is important to choose a braiding pitch suited to the use of the rope (cf. hereafter).

Pre-stretching

The pre-stretching treatment enables the rope length to stabilise under load, by removing the space between the plaits caused by braiding. A pre-stretched Dyneema® rope provides superior mechanical properties. It is more compact and its diameter is inferior as the air has been removed from the braid. The elongation created under load is significantly reduced and the resistance to abrasion is improved because the surface of the fibres in contact with the exterior is smaller.

When one splices a rope, it gives more “puffiness” to the braid. Therefore, it is important to re-stretch the rope after splicing it.

Coating treatment

Coating is a process whereby the rope is soaked in a polyurethane solution. Coating is a heat treatment performed in an oven, at the same time as pre-stretching. Polyurethane forms a film around the Dyneema® twines, which protects them from external aggression (salt crystal, sand, chafing etc.). Rough non-coated Dyneema® is already very resistant to chafing because its friction coefficient is very low: it is a slippery fibre with minimal hooking. Coating reinforces the rope’s anti-chafing properties. The solution also contains colouring that enables the braid to be dyed.Non-coated high modulus polyethylene, which is an oil-derived fibre, is white or black (Black Dyneema®). Purely aesthetic, the Dyneema® colouring is, nevertheless, very practical for identifying different manoeuvres.

A coated Dyneema® braid is much easier to splice because the fibres are stuck to one another.

DYNEEMA® WITH SHORT PITCH BRAIDING (LANCELIN)

Short or long braiding pitches make more elastic braids, but that resist better to external aggression and can withstand a small bending radius: the plaits protect each other and the surface in contact with the exterior is smaller. Dyneema® braids with short braiding pitches are suitable for all attachment systems: lashings, loops, textile shackles.

Braids with extremely tight braiding pitches are very stiff to the touch and impossible to splice! They are designed for specific uses where abrasion is a major cause of wear. Dyneema® rope is used make mast foot downhaul for windsurf boards, for example.

Ideal for connections (lashings, loops, textiles shackles, etc. ) : resistance to abrasion and good structural hold of splices elongation due to the braiding pitch.

DYNEEMA® WITH SHORT PITCH BRAIDING (LANCELIN)

A long braiding pitch provides low elongation when the rope is submitted to load. Dyneema® braids with long braiding pitches are suitable for applications requiring stable length under a high load, so excellent stiffness (vang strops, standing rigging, backstay, running backstay, inner forestay, pole bridles, bobstay, etc).

Excellent stiffness: Ideal for strops (backstays, running backstays, inner forestay, boom vang, etc. )

Resistance to abrasion and bending radius

DYNEEMA® FSE STS (ultra heat-set and pre-stretched)

The ultra heat set and pre-stretched process, also named “heat-setting” in still rarely used because of its cost. It is a process close to that of pre-stretching but at a very high temperature and with a precise hygrometric rate. The tension applied to the rope is also very controlled. The ultra heat set and pre-stretched process aligns the molecular chains along the working axis of the fibres for better stability under load. It also enables the coating to hold better. This recent technology , which did not exist ten years ago, enables the fabrication of “synthetic cables” with identical properties, or even better ones than conventional steel cables. Thermofixed Dyneema® ropes have practically no more elongation, which means that they have reached their working load length. Stable and rapidly functional, they are, therefore, perfectly suitable for standing rigging.

Very low elongation: suitable for lateral standing rigging (shrouds)

Zero creeping: stable length overtime

-

⌀ de 2 à 10 mmRope with low elongation (runners, shrouds, strops…) | 100% Dyneema®0,82 € – 20,60 € TTC

⌀ de 2 à 10 mmRope with low elongation (runners, shrouds, strops…) | 100% Dyneema®0,82 € – 20,60 € TTC -

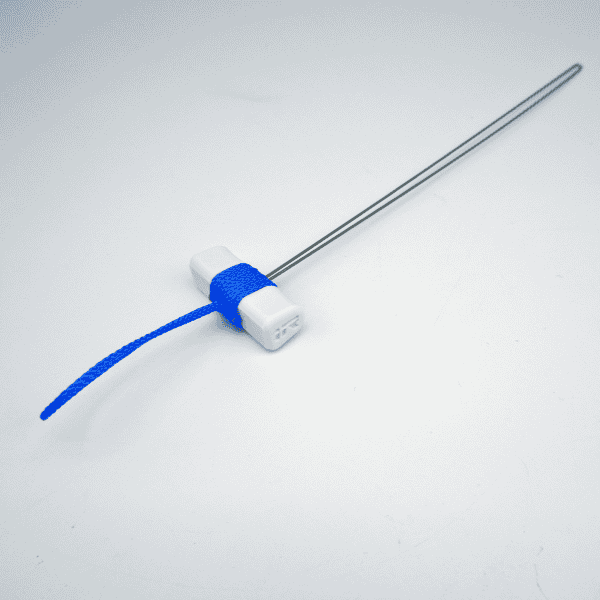

Long eye splicing needles – Special for rope work16,90 € – 24,90 € TTC

Long eye splicing needles – Special for rope work16,90 € – 24,90 € TTC -

Ino-Rope storm lighter6,50 € TTC

Ino-Rope storm lighter6,50 € TTC -

⌀ de 2 à 10 mmLine for lashing, abrasion resistant | Dyneema®1,04 € – 15,12 € TTC

⌀ de 2 à 10 mmLine for lashing, abrasion resistant | Dyneema®1,04 € – 15,12 € TTC