Ino-Block: from the Iron Age to the Textile Age

Friction rings, “standard” blocks: and then?

Before the introduction of the Ino-Block, in the early 2000s, the alien blocks with textile axles flooded the market. Very affordable and with an excellent weight / resistance ratio, they soon became a hit product. But a friction ring is in no way comparable to a block in terms of performance. Indeed, a sheave that rotates around an axle is obviously more efficient !

How does the Ino-Block work ?

For a rope that goes back and forth at 180° in a ring (like a 2-strand block and tackle), the loss of load is about 45% compared to 5% for a ball-bearing block. It seems that friction rings are only suitable for idlers and static loads requiring little settings. Indeed, much more efficient and widely used, ball bearing blocks are, however, far from perfect (even the high-quality models). The balls wear rapidly and are difficult to replace. Not to mention the corrosion of the metallic parts, inevitable at sea. And nowadays, as boats are becoming lighter and lighter (imposed by diets!), their weight and cumbersome volume are more and more penalising. In short, it was time to innovate !

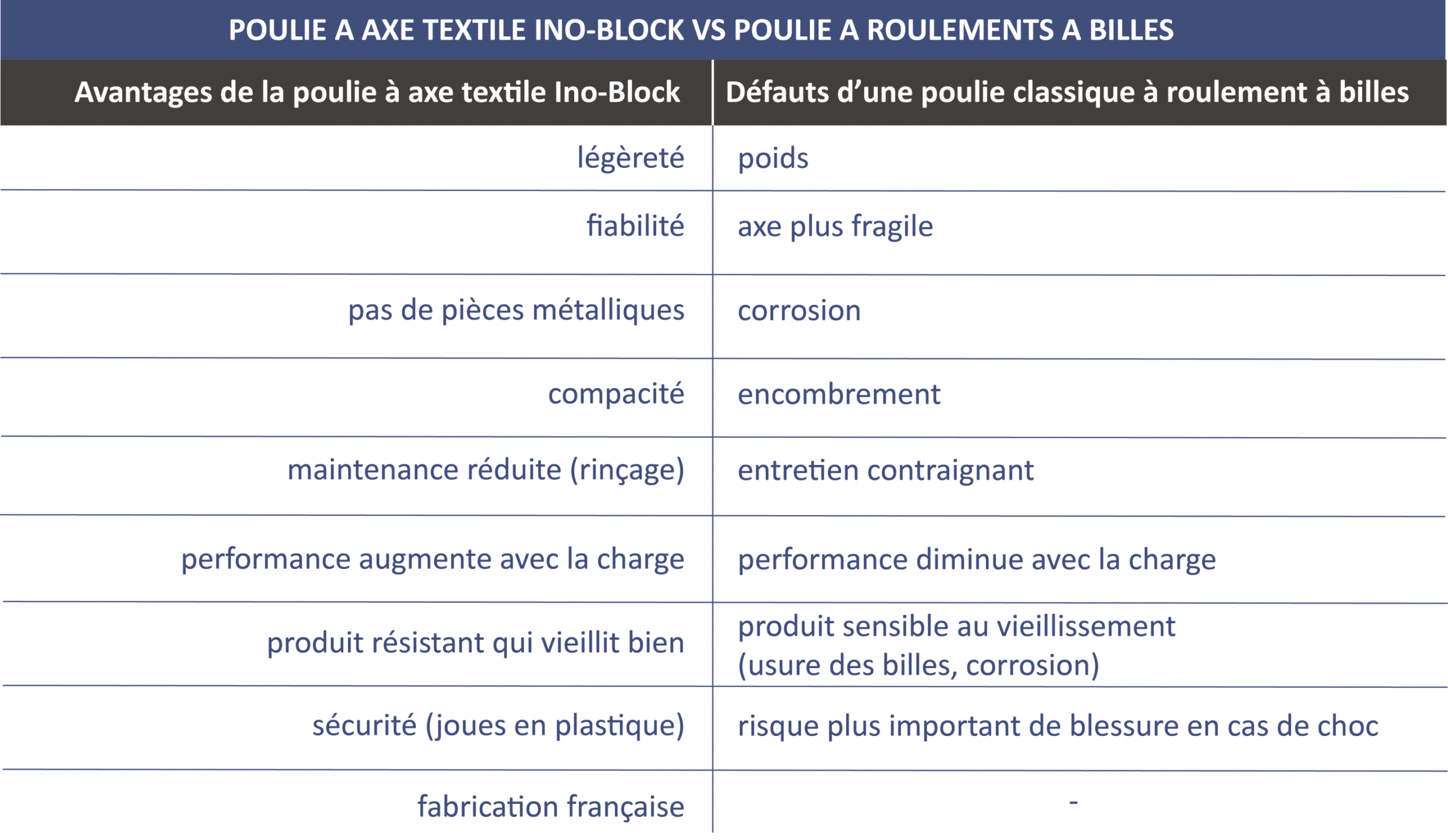

The Ino-Block with textile shackle compared to ball bearing blocks :

The Ino-Block with textile shackle compared to ball bearing blocks :

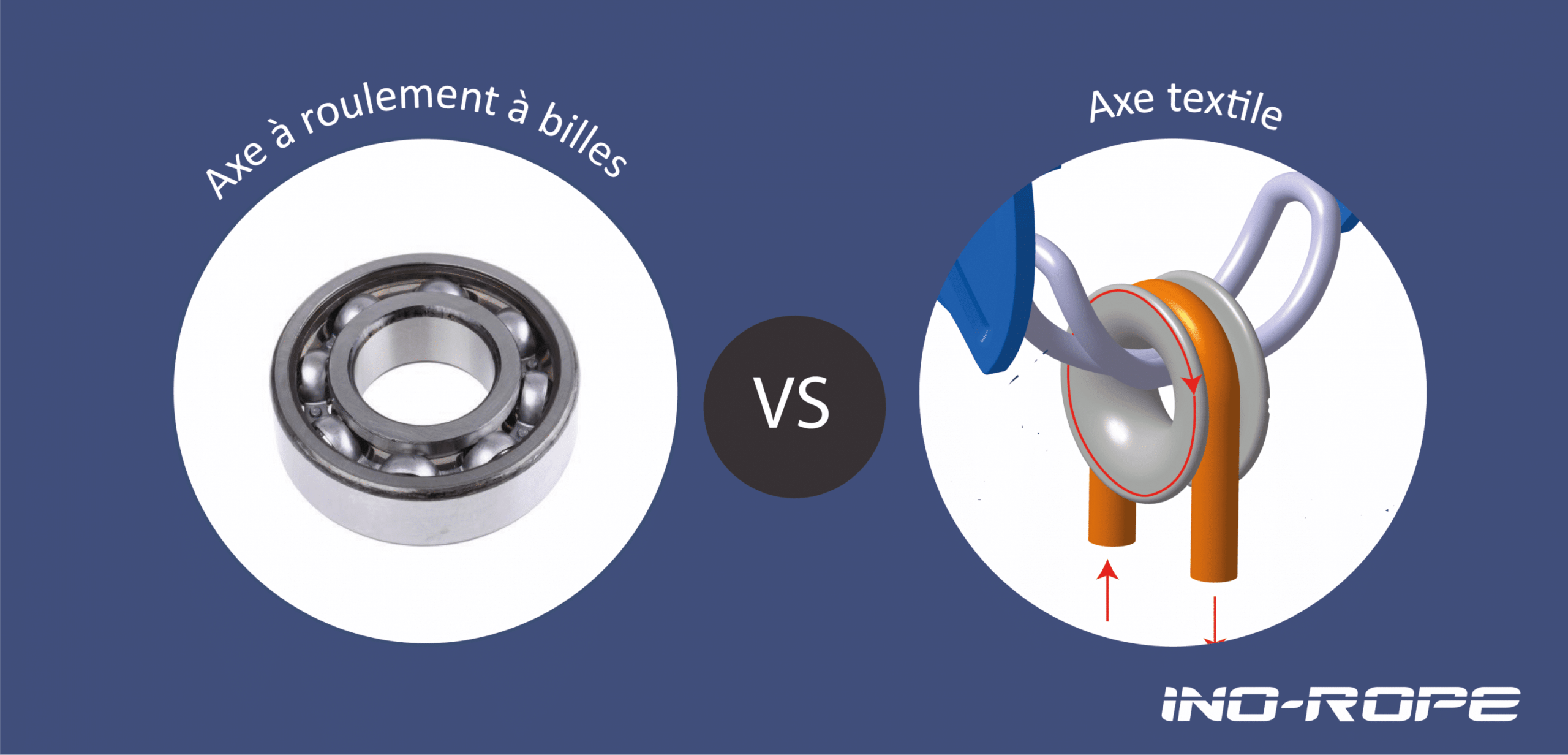

Due to this fact, Ino-Rope designers developed a 100% innovative block (and patented!). In brief, we have combined the qualities of the friction ring, the efficiency of blocks and the advantages of a high-tech textile fibre: Dyneema®. Furthermore, the Ino-Block is the first block on the market with a textile axle. The Dyneema® axle is extremely lightweight and resistant, for optimal reliability !

It would be a mistake not to use it !

The Ino-Block provides excellent performance thanks to minimal friction between the Dyneema® axle (very slippery) and the high-quality anodised aluminium sheave (surface treatment, optimised shape and weight). And unlike a ball bearing block, the efficiency of the Ino-Block increases with the load (See graph). After the running-in phase, the Dyneema® axle self-polishes and becomes even more slippery: like wine, the Ino-Block improves as it ages! The Ino-Block, which is composed of only five parts, relies on an ultra-simple concept. Effectively, it uses materials made to last (no corrosion, only rinsing maintenance needed). Everything is Made in Brittany by our team of professional rigger wizards.

The Ino-Block with textile axle is as efficient as a standard ball bearing block, but it is significantly lighter, more compact and much more reliable! For longevity and minimal maintenance !

The Ino-Block range

The Ino-Block range covers all types of loads and the block with textile axle, produced in series, available in three different models in order to suit all your needs: “classic” block with textile axle (Ino-Block), snatch block (Ino-Snatch-Block) and cable termination (Ino-Ending). The Ino-Block textile block is a concept that has been tested and approved by offshore racers in the most extreme navigation conditions! (no fear!). Effectively, with resistance whatever the conditions and unpaired lightness, the Ino-Block maximises the potential of high-tech fibres (Dyneema®). In other words, it is a gage of reliability and performance. The Steel Age is over, let us now enter the Textile Age!

Dyneema® with no snag !

Thanks to its very low friction coefficient, Dyneema® (the commercial name for high modulus polyethylene) is a highly chafe resistant fibre: everything slides on it! It is an excellent cover for masthead halyards. But like all textile fibres, it does not like shears. And because textile fittings must still coexist with metal on board, do not forget the two golden rules to avoid chafing. The surface area of the stainless steel fittings (padeye for example) that textile connectors are fixed on must be perfectly smooth. Beware of protruding angles! To sum up, if you smooth the angles and keep up the polish, there will be no more glitches !

Vous serez peut-être intéressé par :

-

Ultra-light textile shackle – I-Connect LIGHT 1.23,30 € – 3,70 € TTC

Ultra-light textile shackle – I-Connect LIGHT 1.23,30 € – 3,70 € TTC -

BL : 600 kg⌀ Jusqu’au 8 mmIno-Block LIGHT 0.622,90 € – 23,90 € TTC

BL : 600 kg⌀ Jusqu’au 8 mmIno-Block LIGHT 0.622,90 € – 23,90 € TTC -

⌀ Jusqu’au 10 mmIno-Block LIGHT 1.227,90 € – 29,90 € TTC

⌀ Jusqu’au 10 mmIno-Block LIGHT 1.227,90 € – 29,90 € TTC