GUIDE D’ACHAT

2/3 Textile standing rigging according to your type of boat

For which boats and what programmes is it interesting to have textile standing rigging? What does textile standing rigging impose in terms of installation, tuning, maintenance, lifespan, insurance? Our step-by-step answers.

Textile shrouds, the privilege of regatta racers?

Filament winding and pultruded UD are two highly confidential technologies in the world of leisure boating. The future lies with braided textile cables. Associated with Dyneema®, braiding ensures sufficient, long-lasting textile standing rigging which is more affordable than filament winding or pultruded UD. Leisure boaters seeking to optimise their boat to gain speed are legion. With a hull that’s as smooth as a baby’s bottom, top notch sails, new generation electronics, carefully chosen running rigging and deck hardware, changing the standing rigging is the right way to go to speed things up even more!

From stainless steel to Dyneema®: how does this improve performance?

Why change classic stainless steel standing rigging for Dyneema® braided shrouds? To gain considerable weight in the heights which reduces listing, pitching and swaying from the front to the back. The performance gain (speed and behaviour of the sailboat) is undeniable. Undeniable, considerable, incredible… We could carry on but what you want is FIGURES! Let’s go: on a 54 footer with a mast with three spreader levels, replacing the stainless steel cables for Dyneema® braids divides the weight of the lateral rigging by ten (14 kg versus 140 kg)! Generally, a Dyneema® standing rigging is eight to ten times lighter than stainless steel rigging!

Constraints of textile standing rigging

RIGGING GEOMETRY

Seeing our outrageous and contagious enthusiasm, you are already reaching for the shroud-cutters. But think before you act! Equipping your boat with textile standing rigging isn’t insignificant and isn’t always possible. It cannot apply to boats whose rigging is divided. Installing textile shrouds is too complicated due to the tuning constraints. In the following paragraphs, we review the constraints involved with Dyneema® braided textile cables, which is the most adapted solution to cruising.

BUDGET

Budget varies and depends on the rigging’s geometry. Continuous rigging involves less cable length and fewer tunings so saves 30% on workforce. With two long open shrouds, the great cruising multihulls are the most fortunate because the installation and creation are very simple. But don’t expect miracles. Even in the most basic configuration, Dyneema® braided textile cables are always more expensive than stainless steel shrouds (for more details, refer to the comparative quote of the First 31.7 at the end of this file).

QUOTE

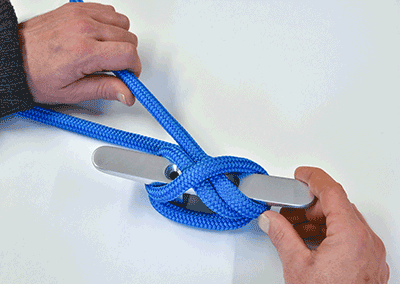

Changing stainless steel standing rigging for textile standing rigging involves several adaptations (points of anchoring on the mast, cable endings, foresail furler). To provide a precise quote, Ino-Rope Riggers need a full assessment of the rigging: length of cables, type of cable (single coil, ROD), references of deck hardware on mast, and/or detailed photos. You will also have to choose how to replace the furler. Most furlers on the market are adapted to a certain diameter and cannot turn around a textile cable. Either you choose a sail that hanks on (a more constraining solution for manoeuvres, but cheaper), or you equip the boat with a structural furler on a non-rotating rope (a more comfortable, yet more expensive, solution). In this case, a non-rotating rope costs about five times more than a stainless steel stay.

TUNING

After setting up textile cables, you need to sail at least three or four times for the Dyneema® braids to stabilise and reach their final length. After this breaking-in period, the shrouds must be tightened. This is no different to stainless steel cables that must be tensioned after the first few miles.

PRECAUTIONS

Textile standing rigging requires more attention than classic standing rigging, since textile fibres are more sensitive to chafing than metal is. Being careful doesn’t mean turning paranoid! The braids are covered so protected on the chafing areas and Dyneema® is a highly resistant fibre. Note than downwind, if the mainsail rests on the shrouds for a long time, this may damage them.

MAINTENANCE

After the installation, we recommend regular visual checking of the sensitive areas to ensure the rigging works well. After this initial monitoring phase, we recommend climbing up the mast at least once a year (this ritual also applies to stainless steel cables). After five years, the shrouds must be taken down to be checked by an Ino-Rope rigger to control the condition of the fibres in the workshop. If there’s nothing to declare, the rigging is off for another five years. The disassembly and reassembly of the rigging must be taken into account for your budget!

LIFESPAN, INSURANCE

And after ten years? If the cables are still in good condition after a second workshop control, they might still be usable. But today, we don’t have enough hindsight on the lifespan of Dyneema® braided textile standing rigging to commit to more than a decade. To conclude, we will answer a question that haunts many of you. Can textile standing rigging be ensured? YES! If it has been created and installed by a professional covered by a civil liability insurance adapted to their activity.

-

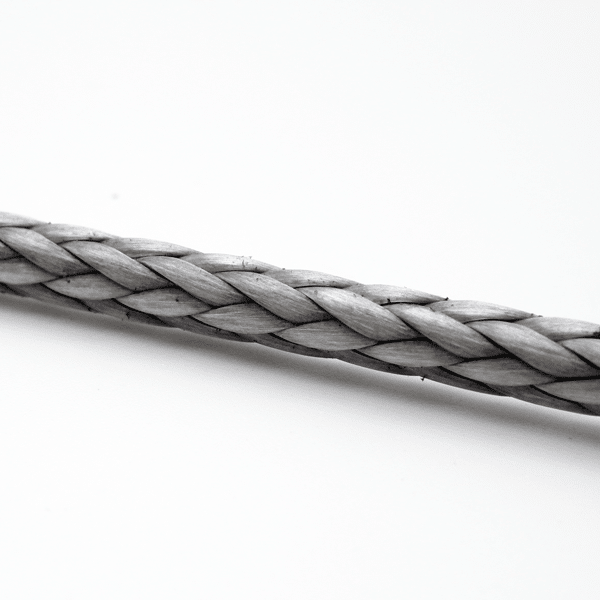

⌀ de 7 à 12 mmRope to splice, SK99 Dyneema® core, SK78 Dyneema® cover9,30 € – 24,18 € TTC

⌀ de 7 à 12 mmRope to splice, SK99 Dyneema® core, SK78 Dyneema® cover9,30 € – 24,18 € TTC -

-

⌀ de 3 à 12 mmDyneema® SK78 braid – High resistance treatment7,20 € – 26,21 € TTC

⌀ de 3 à 12 mmDyneema® SK78 braid – High resistance treatment7,20 € – 26,21 € TTC