GUIDE D’ACHAT

3/3 Which fibres should be used in textile standing rigging?

More and more people, competitive sailors and leisure boaters alike, ask us questions about textile standing rigging. What are the different technologies to make a textile cable?

Which fibres should be used for textile shrouds?

To avoid any misunderstanding, first let’s specify that by “standing rigging”, we mean the fixed parts that ensure the mast holds. The issues concerning backstays, running backstays and quick release baby stays, which are mobile and/or adjustable elements, won’t be mentioned in this file. The stay is also excluded, since in textile standing rigging, this is an anti-twist cable, a product in its own right, with specific technology. In short, all we will talk about here are shrouds.

Within the big fibre family, we will only mention those we are interested in, namely those that are good candidates to create a standing rigging. We will also mention the strengths and weaknesses of each fibre in this respect (we won’t talk about resistance to heat for instance).

Aramids: pioneers in standing rigging!

Different materials are concealed in the word “textile”, with each fibre having its own characteristics. Historically, textile cables were designed with aramids (Kevlar ® or Technora ®), a resistant and stiff material. However, aramids are UV sensitive, which forces us to protect them and limits their longevity somewhat. They are used when performance takes precedence over the durability of the standing rigging.

+ resistance

+ stability

– UV sensitive

PBO: the idol with feet of clay

An extremely resistant and stable fibre, polybenzoxazole or PBO (thank goodness for abbreviations!) fell into step behind aramids in standing rigging confection. Its important weight, due to its high density, is detrimental, as is its very limited lifespan (two years approximately). PBO doesn’t like light, humidity, or chafing (the fibres cut into each other)! And unfortunately, its cost is inversely proportional to its longevity.

+ resistance

+ stability

– weight

– fragility

Carbon: exceptional and confidential

Carbon is an exceptional fibre, reserved for boats that are no less exceptional. Its mechanical characteristics are particularly adapted to standing rigging: unequalled resistance to rupture and stability, longevity that would make a senior person faint. Carbon only fears shocks for its extreme rigidity makes it breakable. A constraint that must be taken into consideration as it imposes regular, thorough monitoring of the rigging.

+ resistance

+ stability

+ lightness

+ longevity

– sensitive to shocks

Dyneema®: the rising fibre

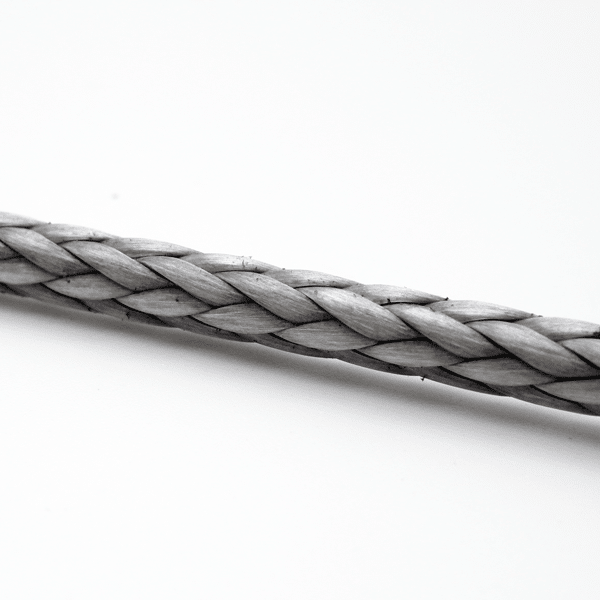

Dyneema® (high modulus polyethylene) is the rising fibre. Eight times more solid than stainless steel of the same diameter, its resistance to rupture is superior to that of aramids and its elasticity is very low. Other than an optimal weight/resistance ratio, Dyneema has the advantage of being durable: it’s highly resistant to chafing and UV. Its longevity is estimated at ten years approximately.

The weakness of Dyneema is creeping, which is the irreversible elongation of the fibres under static load, meaning when they work for too long beyond a certain tension (25% of the breaking load). Creep is incompatible with the required stability for standing rigging. The solution consists in over-sampling the shrouds so that they always work below 25% of the breaking load: as such the creeping zone is never reached.

+ resistance

+ lightness

+ durability

– elongation under static load!

-

Special rope scissors (Dyneema®, Kevlar®)44,90 € – 49,90 € TTC

Special rope scissors (Dyneema®, Kevlar®)44,90 € – 49,90 € TTC -

⌀ de 7 à 12 mmRope to splice, SK99 Dyneema® core, SK78 Dyneema® cover9,30 € – 24,18 € TTC

⌀ de 7 à 12 mmRope to splice, SK99 Dyneema® core, SK78 Dyneema® cover9,30 € – 24,18 € TTC -

-

⌀ de 3 à 12 mmDyneema® SK78 braid – High resistance treatment7,20 € – 26,21 € TTC

⌀ de 3 à 12 mmDyneema® SK78 braid – High resistance treatment7,20 € – 26,21 € TTC