Which fibre for which use?

A chafe sleeve protects rope where there is exposure to chafing (cleats, sheaves, winch, etc.)). The role of a chafe sleeve is to increase the rope’s lifespan: when it is worn, it is changed rather than having to replace the rope. This practical brief will help you to choose the right chafe sleeve (Dyneema®, Technora®, polyester, mixed), depending on its use.

Technora® chafe sleeve: for rope exposed to overheating

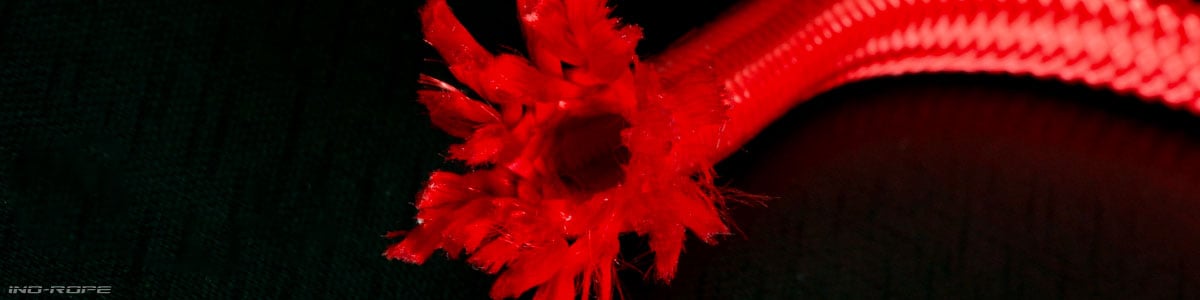

A chafe sleeve made of Technora® is manufactured with Aramid fibres appreciated for their excellent resistance to overheating (up to 450 °C). Aramids also have a high friction coefficient, which means that they are not very slippery: the fibres “grip” the surface that they rub against. Resistance to overheating and Technora®’s high friction, make it ideal for winch chafe sleeves on large sailing yachts. An abrupt release of the genoa sheet causes overheating of the rope, which could melt! The solid structure of the Technora ® chafe sleeve, with its high friction coefficient, provides another advantage: the rope does not slip around the winch. This is also why clutches and cleat chafe sleeves are made of Technora®. However, Aramids have a nasty flaw. Their lifespan is limited to two years because of their low UV resistance (the fibres eventually form bobbles).

Resist to over-heating (brutal easing on winch)

Good holding in clutches

Limited lifespan (UV sensitive)

One should avoid using Kevlar® (Aramid fibres) for chafe sleeves: Because of its yellow colour, it is even more UV sensitive than Technora®, which is black.

Dyneema chafe sleeve®: ideal for masthead sheaves

A common belief is that Aramids (Technora® and Kevlar®) are the most abrasion resistant fibres… But it is wrong! The fibre that is at the top of the charts in abrasion resistance is polyethylene high modulus, marketed under the brand name Dyneema® (or Spectra®). The latter also has a very long lifespan, unlike Technora®. A chafe sleeve made of Dyneema® resists very well against salt and UV aggressions. Unlike Aramid fibres, high modulus polyethylene has a very low friction coefficient: it is an extremely slippery fibre. Besides, it withstands low bending radius very well. Dyneema® chafe sleeves are perfectly suitable for protecting halyards, at the masthead, around the sheaves and the guide (through which the rope passes). They provide both minimal friction and very good resistance to wear (UV, chafing). Do not hesitate to put them on the foresail sheets, around the shrouds, or even on the cunningham, where the rope passes through the mainsail tack ring. However, Dyneema® chafe sleeves must not be used on clutches and cleats, under any circumstances: it is much too slippery!

Abrasion resistance and lifespan

Chafe sleeve for halyard:minimal friction in sheaves

Does not hold in clutches

As well as being aesthetically pleasing, the Dyneema® chafe sleeve’s coating increases its lifespan (protection against salt and UVs).

Polyester chafe sleeve: multi-purpose but less efficient

The chafe sleeve made of polyester is a consumer product that can be found in all ship-chandlers that are fully stocked. Polyester’s success is not only due to its low cost. It is a durable fibre with low sensitivity to UVs and to abrasion. A polyester chafe sleeve wears out much less quickly than a Technora® one. Additionally, it is three times less expensive than a Dyneema® one. The polyester chafe sleeve is not the most efficient solution but it is an all purpose product that can be suitable for the protection of masthead ropes (sheaves and guides), as well as for clutches and cleats. Therefore, it is an efficient solution for those who wish to control their budget, while increasing their ropes’ longevity.

UV resistant fibre

Multi-purpose chafe sleeve

Cost-saving but less efficient

Whatever type of chafe sleeve is used, it must be correctly fitted: if it comes off the rope and gets stuck in the sheave or the cleat, here comes trouble!

Mixed polyester-Technora® chafe sleeve: A must in the clutch range

The mixed polyester-Technora® chafe sleeve is the best compromise for clutch chafe sleeves. The high friction coefficient of Technora® ensures excellent grip in clutches and cleats. Technora® also provides very good abrasion resistance. Polyester, on the other hand, compensates for Aramid fibres’ weaknesses. A mixed polyester-Technora® chafe sleeve is, indeed, more supple than a 100% Technora® chafe sleeve. When it ages, it becomes stiff and unpleasant to touch; Aramid fibres harden when exposed to UVs. Moreover, polyester significantly increases the lifespan of the chafe sleeve, as its UV resistance is much higher than that of Technora®. Thus, a mixed polyester-Technora® cover combines longevity, suppleness of the rope, abrasion resistance and good holding power in clutches and cleats.

Lifespan: UV resistance

Abrasion resistance and good grip in clutches

Rope suppleness

Whatever it is made of, a chafe sleeve increases the rope’s diameter significantly. Remember to check whether your fittings are suitable !

-

Thick chafe sleeve (standing rigging) | Dyneema®3,42 € – 13,46 € TTC

Thick chafe sleeve (standing rigging) | Dyneema®3,42 € – 13,46 € TTC -

Dyneema® SK78 chafe sleeve – thin – black3,60 € – 16,08 € TTC

Dyneema® SK78 chafe sleeve – thin – black3,60 € – 16,08 € TTC -

Blended Technora® and polyester chafe sleeve3,17 € – 7,79 € TTC

Blended Technora® and polyester chafe sleeve3,17 € – 7,79 € TTC -

Thin chafe sleeve (Standing rigging) | Dynnema®3,92 € – 14,63 € TTC

Thin chafe sleeve (Standing rigging) | Dynnema®3,92 € – 14,63 € TTC