Creep, elongation: should this be a source of worry ?

When one speaks about Dyneema® rope creeping, what is it exactly? One often confuses elongation resulting from construction, elongation at break and creeping. What is pre-stretching on a rope? How elastic are the fibres? From which working load does creeping begin? Is it a constraint for the use of Dyneema® on running or standing rigging? Ino-Rope answers each of these questions, which are a source of discussion on the docks, point by point.

Pre-stretching: stabilisation of the rope after braiding

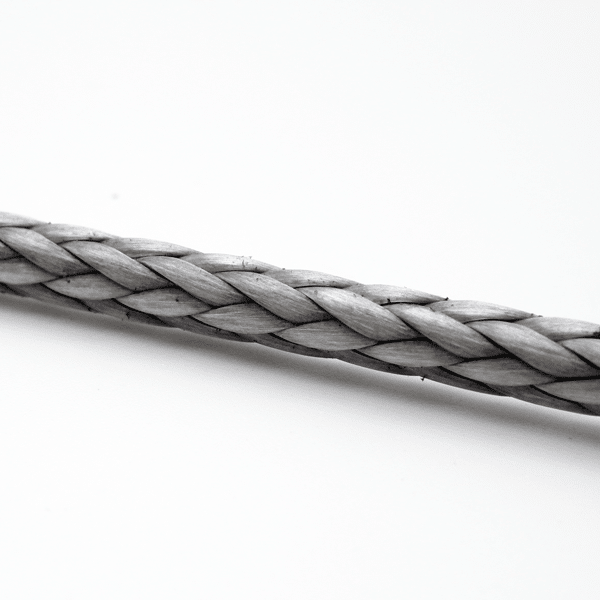

First, a Dyneema® rope is a hollow braid comprised of a variable number of plaits (12, 16, 24… ). Effectively, each plait is made of a certain number of fibres. These fibres, which were straight before the construction of the rope, are then shaped like an S, once the rope has been braided. If the braid is not tightened after its confection, it will certainly undergo elongation, following its first use because the S-shapes formed by the fibres will stretch. This “initial” elongation is not due to the mechanical properties of the fibre but to the stabilisation of the braiding process under load. To avoid this, rope manufacturers have elaborated a technique called pre-stretching. The process simply consists in stabilising the length of the braid by stretching it, so that the S-shapes formed by the fibres are straightened to their utmost.

Heat-setting and pre-stretching process: state of the art technology

First, a Dyneema® rope is a hollow braid comprised of a variable number of plaits (12, 16, 24… ). Effectively, each plait is made of a certain number of fibres. These fibres, which were straight before the construction of the rope, are then shaped like an S, once the rope has been braided. If the braid is not tightened after its confection, it will certainly undergo elongation, following its first use because the S-shapes formed by the fibres will stretch. This “initial” elongation is not due to the mechanical properties of the fibre but to the stabilisation of the braiding process under load. To avoid this, rope manufacturers have elaborated a technique called pre-stretching. The process simply consists in stabilising the length of the braid by stretching it, so that the S-shapes formed by the fibres are straightened to their utmost.

Elongation to break or elastic properties

The degree of elongation to break corresponds to the elasticity of the rope when it is subjected to high tensile load. Let us take the case of the halyard of the mainsail, which stretches in a gust. It behaves like an elastic: once the tensile load decreases, the halyard returns to its initial length.

Elongation to break can be changed

It affects the boat’s performances by modifying the tension on the luff and thus, the setting of the sails. This results in a loss of power. Dyneema® elongation to break is about 3.5%, which is 3.5 m on a 100 m long rope that would be used at 100% of its breaking load. For a normal working load (10 to 15% of the breaking load), a Dyneema® halyard, subject to tension along 15 m, stretches less than 10 cm (compared to 45 cm for a polyester halyard)! Needless to say, that is peanuts…

Creeping or chewing-gum properties

Dyneema® behaves like chewing-gum: if it is subjected to continuous significant tension; it stretches incessantly and permanently. It is this irreversible elongation under static load that is called “creeping”. Nevertheless, the risk of creeping occurs only if the rope is used beyond 20% of its breaking load. If you are overcome by the fear of going beyond that fatal 20% limit, rest assured! That threshold is never reached with “regular” working loads, which remain at around 10-15%. Basically, unless you are racing in the Vendée Globe on a 60 foot IMOCA, you will never have to worry about creeping !

DYNEEMA®, Kevlar®, or PBO: what are the differences ?

Unlike Dyneema®, Kevlar® (an aramid fibre) and PBO offer excellent stability under static load: there is no creeping effect. But, as the Dyneema creeping problem is not an issue because it only affects ropes that undergo extreme conditions, this advantage does not make any difference.

What is the best choice?

Other points, however, tilt the balance towards Dyneema®. PBO’s elongation at break is inferior to Dyneema’s ® (between 1.5 and 2% as opposed to 3.5%) but this fibre is twice as heavy and three times as expensive! Elongation to break and the prices of Dyneema® and Kevlar ® are identical, but the latter is 35 to 40% heavier. Finally, in terms of durability, Dyneema® lasts much longer than Kevlar® and PBO, which are very sensitive to UVs, chemical products, abrasion and intense bending radius… And that is already a lot!

Contrairement au Dyneema ®, le Kevlar ® (une fibre aramide) et le PBO ont une excellente stabilité sous charge statique : il n’y a pas de phénomène de fluage. Mais vu que le problème du fluage du Dyneema n’en est pas un puisqu’il ne concerne que les cordages soumis à des conditions extrêmes, cet avantage ne fait pas la différence. D’autres arguments font par contre pencher la balance du côté du Dyneema ®. L’allongement à la rupture du PBO est inférieur à celui du Dyneema ® (entre 1,5 et 2% contre 3,5%) mais cette fibre est deux fois plus lourde et trois fois plus chère ! L’allongement à la rupture et le prix du Dyneema ® et du Kevlar ® sont identiques, mais ce dernier est 35 à 40% plus lourd. Enfin, la longévité du Dyneema ® est bien meilleure que celle du Kevlar ® et du PBO qui sont très sensibles aux UV, aux produits chimiques, à l’abrasion et aux forts rayons de courbure… ce qui commence à faire beaucoup !

-

Product on sale⌀ de 4 à 20 mm-20%12-plait UHMWPE single braid1,66 € – 19,70 € TTC

Product on sale⌀ de 4 à 20 mm-20%12-plait UHMWPE single braid1,66 € – 19,70 € TTC -

⌀ de 5 à 16 mmRope for frequent use (cruising, regatta…) low elongation | Dyneema®2,22 € – 22,16 € TTC

⌀ de 5 à 16 mmRope for frequent use (cruising, regatta…) low elongation | Dyneema®2,22 € – 22,16 € TTC -

⌀ de 7 à 12 mmRope to splice, SK99 Dyneema® core, SK78 Dyneema® cover9,30 € – 24,18 € TTC

⌀ de 7 à 12 mmRope to splice, SK99 Dyneema® core, SK78 Dyneema® cover9,30 € – 24,18 € TTC -

⌀ de 3 à 12 mmDyneema® SK78 braid – High resistance treatment7,20 € – 26,21 € TTC

⌀ de 3 à 12 mmDyneema® SK78 braid – High resistance treatment7,20 € – 26,21 € TTC